Are switched reluctance motors the "LEDs of Motors"?

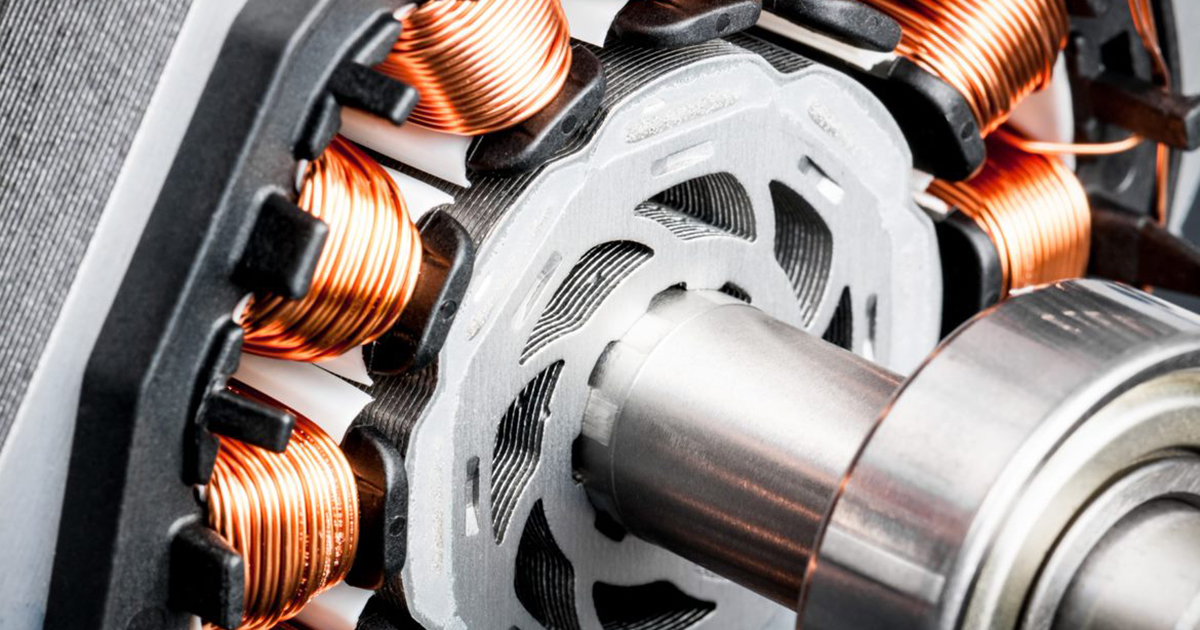

For decades, we've heard industry folks refer to switched reluctance motors (SRMs) as the "LEDs of motors." If we could simply swap out existing fan motors with SRMs, we could improve the efficiency of HVAC systems and enjoy the instant energy savings. The concept for SRMs has been around since at least the 1970s, but until recently they've never been practical to produce at scale.

Today more companies have begun manufacturing SRMs for widespread installation. According to the U.S. Department of Energy, electric motor‐driven systems account for 68 percent of the total electricity used in manufacturing, driving energy-intensive processes such as refrigeration, pumps and facility HVAC systems. If we could conserve that energy with a better—and more sustainable—type of motor, it certainly would be a breakthrough akin to LEDs.

To verify the energy impact of these motors, we conducted a study for the ComEd Energy Efficiency Program to evaluate the benefits and potential barriers to retrofitting rooftop HVAC units (RTUs) in commercial buildings with SRMs. Our study looked at the different energy consumption patterns pre– and post-installation of SRMs across heating, cooling, and shoulder seasons. We assessed annual performance since any worthy alternatives need to perform year-round.

How much do switched reluctance motors save?

In the field study, we found direct savings in retrofitting RTUs with single-speed fan motors:

- 61 percent annual energy savings for RTU supply fans

- 39 percent annual savings at the RTU level

Using the best available data, we extrapolated these findings to the ComEd service territory to determine the potential savings at scale. In ComEd's case, retrofitting all RTUs with single-speed SRMs would save 907 million kWh and 100 million dollars annually. Still, no matter the utility, it's clear that SRMs save significant energy when applied correctly.

We also asked installers about differences from conventional fan motor retrofits. Though none of the installers had previous experience with SRM motors, many mentioned that the installation was comparable to a conventional motor. The major difference is the need to install the motor controller, which is a small "brain" that provides real-time feedback and controls capabilities to the SRMs. Even with this added step, there are few barriers to scaling SRMs from an installer's perspective.

What kind of buildings are best for SRMs?

Utility programs can prioritize saving energy and money by identifying buildings with heavy use of air handlers.

These building types may include:

- Convenience stores that keep 24/7 hours

- Banks, offices, and other retail settings where conditioning is important to occupant comfort

Though outside the scope of our field study, one could imagine other applications where more air equals more savings. For example, in office buildings where COVID-19 concerns have led some building owners to overhaul ventilation, SRMs could help offset the costs of added energy use from higher exchange rates.

"The LEDs of motors"?

In terms of energy savings, we at Slipstream believe that SRMs could be to traditional motors what LEDs are to incandescent lightbulbs. Whether that potential transforms into savings depends on whether the deployment of SRMs compares to that of LEDs in recent years.

When combined with high-performance strategies, such as integrating networked lighting and HVAC controls, SRMs can lead to even greater savings. If rolled out smartly, SRMs just might become as essential to energy efficiency programs as traditional lighting swaps once were.

Find more information about the SRM Field Evaluation on the ComEd Customer Innovation website.