Employee caught in the Slipstream: Sam's journey to net-zero

At Slipstream, we have employees who want to walk the talk when it comes to energy efficiency. Sam Simonetta is one of those people. Sam considers himself fortunate to be able to live net-zero (NZ) in a home he and his wife, Christine, designed and built -- with a lot of help. As a kid, Sam dreamed of generating his own electricity from wind power, and in 2001 he and Christine decided it was time to make that happen. Their aspirations didn’t take shape overnight though. Their journey to NZ living happened over 9 years – after re-locating from Michigan’s lower peninsula to the Upper Peninsula (U.P.), lots of coursework at the Midwest Renewable Energy Association (MREA), months of design, grant writing, sponsor “courting,” construction, and even more grant writing.

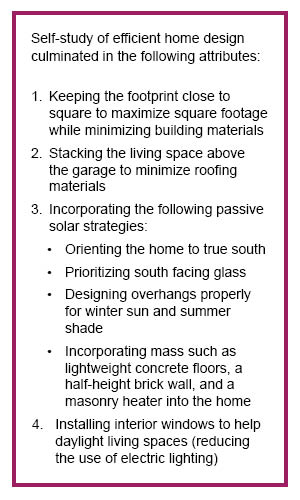

A residential wind turbine requires a good deal of open space, which was scarce at the Simonettas’ lower Michigan home. Fifteen acres on Onota Hill in the U.P. was just the ticket. When the couple discovered Michigan’s 2003 “5-Star Home Grants,” they were inspired to take advantage of this small stipend and the opportunity to educate others about more modest home design, conservation, energy efficiency, and renewable energy.

With an almost 6-month winter and lots of snow, a 12/12 pitched roof would not only shed snow well but provides extra living space. Finally, minimizing construction waste and incorporating old interior doors, light fixtures, an old Mackinac Bridge beam, and other salvaged items when available would help “green” the home and add character.

Completed in 2005, the home was built with structural insulated panel walls and insulated siding (R-27), low U-value, triple-pane windows with solar heat gain coefficients specifically chosen for north, east, west, and south sides, and an Icynene insulated, vented roof (R-55). A high-efficiency Munchkin propane boiler provided in-floor radiant heating and indirect water heating. A front-loading washer, 1.75 gallons per minute showerhead, low-flow sink aerators, and a salvaged toilet retrofit with a dual-flush kit helped save water. Heat loss and water waste in long plumbing runs was minimized by installing point-of-use water heaters at kitchen and bathroom sinks. To ensure a supply of fresh air for this tightly built home, an energy recovery ventilator was installed, exhausting air from bathrooms and near the kitchen while supplying fresh, preheated air to the living space. Compact fluorescent lighting was incorporated throughout, except in areas where lights would only be used momentarily.

What about phantom loads?

While power strips made it possible to totally turn off the computer, stereo, and TV, what about ground fault circuit interrupter (GFCI) receptacles, required by building codes in kitchens and bathrooms (another phantom load!)? To eliminate this draw, standard switches were installed ahead of the GFCI’s so those receptacles could be turned off when not in use. The tough one was the digital clock on the electric stove! Since it’s hard to find a 40A double-pole switch that fits conveniently near a kitchen island stove, that phantom load always remains lurking in the house, day and night.

Wind power

The beauty of wind power in a heating dominated climate is that the renewable resource matches the energy need. That is, when you need the most energy (winter), the wind resource is the most abundant. After a thorough electric load analysis, Sam determined that a 2.5 kW wind turbine should cover all electric loads including the electric stove and dryer. Thanks to conservation efforts, and after a few years of their turbine consistently producing more energy than they were using, the couple thought, “Wouldn’t it be cool to commute on that excess electricity?” By late 2008, their conversion of a Chevy S10 to all-electric was complete, and the Simonettas were able to drive some of their 48-mile round-trips to Marquette on wind power!

GreenMax Home Grant

In 2009, Sam learned about WPPI Energy’s GreenMax Home grant which provided funding assistance for building or renovating a home to NZ. Since WPPI was the provider for their local electric cooperative, the couple began the final step in their journey. Earning this grant helped them replace their propane boiler with an innovative, highly efficient, air-to-water heat pump (Daikin Altherma), add supplemental insulation, add whole-house on-demand water heating, and replace their 2.5 kW wind turbine with a Bergey 10kW model to provide the power. As part of the grant, the Simonettas agreed to monitor their home’s energy performance for a minimum of 12 months to assess energy savings and assure NZ performance due to the home’s enhancements.

The Journey Continues

Since 2010, Sam and Christine have continued to add energy and water-saving features to their home. LED lighting is installed as compact fluorescent lighting burns out, to fully utilize these mercury (Hg) containing lamps before sending them off for recycling. Their self-converted electric vehicle has been replaced by one with longer range to provide more wind-powered driving. They’ve installed dual-flush and 0.8 gallons per flush toilets, and now use a heat pump water heater for the majority of water heating. The least common device they’ve incorporated is a small, residential ozone generator, allowing them to wash clothes in cold water without detergent.

Yes, Sam is a self-admitted geek. But, he and Christine are trying to walk the energy efficiency and renewable energy talk. They feel there’s an urgency to educate the masses about climate disruption and what we can do to help curtail it. And though they don’t have kids, they’re on a mission to help preserve our Mother Earth for future generations.

Do you have questions for Sam? Feel free to reach out at ssimonetta@slipstreaminc.org.