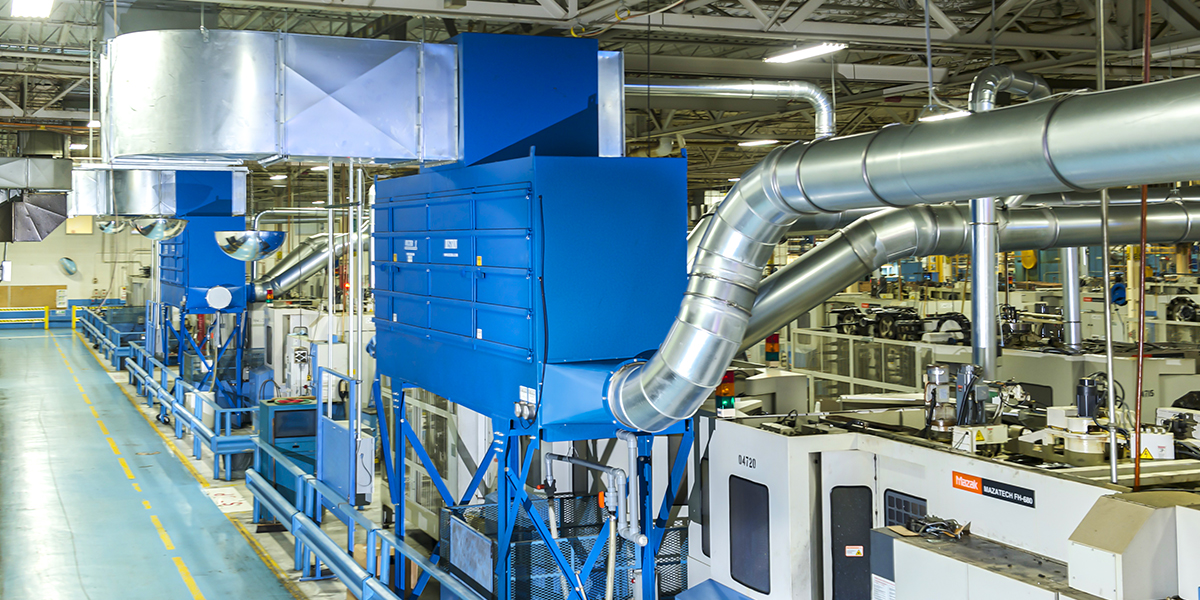

Energy reduction opportunities in industrial dust collection systems

It’s one thing to control your dirty air from manufacturing processes, it’s another to do it intelligently! Modern industrial dust and fume collection systems typically lack the controls and monitoring needed to be truly energy efficient. In this webinar, our expert presenters will help you understand your dust collection system and give you the tools you need to optimize its performance and energy use. You will learn how to:

- Generate a simple block diagram of your system

- Estimate energy cost

- Recognize and address typical problems and maintenance issues associated with these systems

We will showcase the elements required for a high-performance industrial fume and dust collection system. The webinar will conclude with a review of case studies that highlight potential energy reduction opportunities associated with improvements like VFDs, blast gates, and intelligent controls.

What you'll learn:

- Estimate the energy cost associated with a typical dust and fume collection system

- Recognize and address typical problems and maintenance issues associated with these systems

- Identify elements of a high-performance dust and fume collection system

- Describe potential energy reduction opportunities

Meet our speakers

Jerry Eaton, P.E., Senior Industrial Energy Advisor

JEaton Consulting, LLC, WAEE President

Jerry Eaton, P.E., is an energy consultant with over 25 years’ experience in energy, utilities, and facilities engineering. He has expertise in manufacturing, project management, process improvement and leadership/technical training. His experience includes 21 years of dedicated service in the US Navy, including the operation and management of nuclear reactor power plants for fast attack submarines. Working as the Energy and Utilities Director of the Facilities Department at Mercury Marine Corporation, he was instrumental in developing and implementing a corporate wide Energy Management Program. He received the 2006 Wisconsin’s Governor’s Award for his work in Energy Management. Jerry is actively involved with the Wisconsin Association of Energy Engineers (WAEE) and the Wisconsin Energy Efficiency Exposition. Jerry has an A.S. in Electrical Engineering, a B.S. in Nuclear Engineering, and an M.S. in Engineering Management.

DuWayne Bohrer, Product Manager

Hastings Air Energy Control, Inc.

DuWayne draws on 29 years of experience in the industrial air cleaning and ventilation energy control environment. He led the group that developed the automation controls which save companies thousands of dollars by optimizing performance for new and existing systems. DuWayne believes in delivering specialized solutions based on carefully chosen equipment models to achieve value for businesses. With experience in every phase of the design-build process, DuWayne is an expert in helping businesses meet codes, standards, and regulations while delivering systems that provide the lowest cost-of-ownership.

Kevin Rohde, President and Chief Operating Officer

Ivec Systems

Kevin has 14 years of experience in the industrial sector and over 27 years of national leadership. With a focus on improving business processes and delivering results, Kevin’s experiences give him unique insights into making business improvements from the business customer perspective. As General Manager and part owner of Hastings Air Energy Control Kevin continually improving processes to serve the Industrial ventilation air cleaning marketplace. This included introducing a proprietary energy management system to a national distribution network. Now, leading the Ivec Systems Company, he has helped refine an operational model that designs, builds, assembles, and supports industry leading Intelligent Ventilation Energy Control products and services.

Questions?

Please see our Education & Training FAQ, or visit our webinar catalog to access Slipstream's entire collection of on-demand recordings.