The State of Commercial Electrification: HVAC

A decade ago, there wasn't a clear mainstream path to electrify commercial HVAC systems in cold climates. As the market demanded solutions, manufacturers hit the lab to advance heat pump technologies. Within the last five years, air-source variable refrigerant flow (VRF) systems—a type of heat pump—have proven to be effective solutions to electrification—especially in cold climates.

Today we can be confident that VRF and other heat-pump technologies are the solution to electrify commercial HVAC systems. And today is the best time to get them into buildings.

Commercial heat pump technologies

Heat pump technologies such as VRF have proven to be successful in moderate climates for several decades. There is still a lack of understanding and awareness of this technology in cold climates, where 55% of total building energy use comes from space conditioning—and 40% of that comes from heating alone.

Heat pumps have two common applications in commercial HVAC:

- Variable refrigerant flow (VRF): Efficient, effective, and powerful, VRF is the premier commercial heat pump technology. It's also seen the latest technology advancements from manufacturers. However, it's also expensive to install. That high up-front cost often limits VRF to higher-end projects or projects with very specific requirements for space conditioning.

- Rooftop units (RTUs): If VRF is the Ferrari of commercial heat pumps, RTU is the Chevy Silverado—utilitarian, cheaper, and powerful enough to get the job done. But manufacturers have seen little reason to advance RTU technology, and heat pump RTUs have limited performance in cold climates—especially compared to VRF.

|

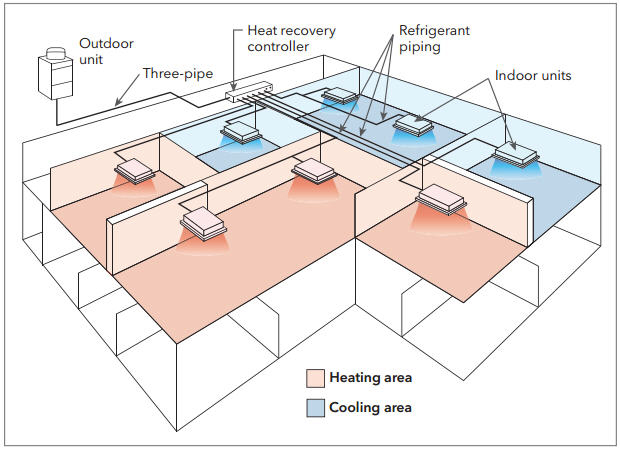

| Variable refrigerant flow systems can deliver cooling to some zones and heating to others, with no reheat needed. This diagram shows an air-source system. |

Heat pumps are a leading electrification solution in all climates due to their efficient operation. Through energy modeling, Slipstream has found that heat pump RTU systems increase electricity consumption by 20–50% and decrease gas usage by 100% over existing gas-fired RTUs.

VRF is even more efficient. So far it's been the high-end solution to electrification, but we can make it more commonplace. High-performance engines—even things like backup cameras and Bluetooth connections—started in fancy cars before they trickled down to everyday vehicles. To spur mass adoption, we need to get VRF technology into the field, test it, and report results.

Field study: proof that VRF works in cold climates

In a field study for Michigan Electric Cooperative Association (MECA), we monitored VRF systems at two hotels—both located in Michigan's notoriously frigid climate. At each site, we collected data on energy usage, space temperatures, and VRF supply temperatures for at least 12 months to ensure that we captured seasonal performance.

A building could achieve zero carbon emissions if it were to combine VRF with onsite renewable energy.

Using this data, we were able to calculate the energy savings of VRF over two typical hotel HVAC systems:

Not only did the VRF system yield energy and cost savings, it also resulted in reduced emissions. A building could achieve zero carbon emissions if it were to combine VRF with onsite renewable energy.

VRF also proved to improve the experience for hotel occupants. Based on interviews with the hotel owners, guests were satisfied with the temperature control within their rooms and the quiet operation of the system. In fact, some guests mistakenly thought the system wasn’t responding to the thermostat because they never heard it kick on or felt a draft from a hole in the wall. At one site, an owner reported fewer HVAC-related complaints.

This field study proves that VRF can help buildings achieve energy savings and carbon reduction targets in cold climates. More demonstration sites would grow this body of evidence and support national awareness.

What's next: building types to electrify now

Not every building can afford to adopt VRF right away. However, owners of certain types of buildings can form the vanguard for widespread electrification. Here are some opportunities we can seize right now.

- Buildings where owners have aggressive carbon reduction goals. VRF can have an immediate impact on emissions when paired with onsite renewable energy.

- New buildings, or existing buildings using electric resistance heating (such as many commercial buildings in the northeast). Efficiency gains will translate immediately into cost savings.

- Buildings undergoing adaptive reuse due to occupancy changes. The transformation presents a chance to electrify and get ahead of the curve.

- Buildings focused on lifecycle costs where a decade-long payback makes sense. Institutional buildings led the way in green buildings; now they can lead in electrification.

Institutional buildings led the way in green buildings; now they can lead in electrification.

No matter the timeline, medium-sized buildings, such as open-air office buildings, are prime candidates for VRF as a solution. Ducted or ductless mini-split heat pumps might make more sense for smaller buildings' heating loads. As for our largest buildings, we need more research into deep energy retrofits before we can fully recommend an electrification design strategy.

Breaking the barriers to VRF adoption

All in all, the mechanisms to electrification are clear. Here are four recommendations to accelerate VRF adoption.

- Increase market awareness of and confidence in VRF and heat pump RFUs. Expand education and training for design firms, manufacturers and distributors, owners and developers, and facility managers. See our free webinar on VRF in cold climates.

- Overcome high first costs. Incentives need to come from all fronts—federal, state, and utility programs all have a role to play. Financing and incentives should account for the high installation costs and the increased operational costs versus gas-fired systems. Programs should target the building types we’ve identified as the best candidates to electrify now.

- Support training for installation and service contractors. Installing a refrigerant-based VRF system is quite a shift from more traditional HVAC systems. Programs should include incentives for installers to take training courses—and for owners to hire certified contractors.

- Present HVAC electrification as a key step to decarbonization. Either VRF or heat-pump RTUs can serve as a milestone to meeting carbon goals. Once space-heating electrification is in place, a building can move on to deeper energy savings from things like GEB implementation and onsite renewable energy.

Commercial electrification and VRF resources

Learn more about VRF

Read our page on variable refrigerant flow for an in-depth look at the technology.

Read about the MECA pilot

Download a PDF of the full report for our MECA study, which includes more details on our data analysis and recommendations.

Watch a free webinar

View our free webinar at Slipstream’s learning portal: Commercial building electrification: Accelerating decarbonization in cold climates

Get involved: join a pilot

We are currently recruiting for more VRF pilots. If your building is located in Minnesota, submit your building as a demonstration site to help prove the technology (and receive financial incentives).